It has taken me way to long to get another update out on this so apologies, the quick update is that the YBR125 is completed and with it’s new owner. However getting it to that stage didn’t go to plan…

Getting It Running

Wind back to the start of April and I had the week off, one of my prime goals for that week was to get the YBR running and ready for an MOT. In my last update I had bolted the shiny bits on and had parts coming to confirm my diagnoses of the Fuel Pressure regulator, it turned out my diagnoses was correct. After draining the tank for what felt like the millionth time I took the fuel pressure regulator off of the donor pump and removed the rust filled one that was on the existing pump assembly. Bolted it all back together and filled it up with some fuel, it immediately sparked into life almost on the first stroke and rev’d cleanly unlike before.

However all was not well, I immediately rolled it down the drive to test that it would go through the gears and thats when it tried to wheelie on me as I kicked it down into gear with the clutch in. The years of sitting had obviously not been kind to the clutch which was now seized.

So i tried a couple of quick tricks first, getting the bike properly warm and the oil properly flowing then dumping it into gear. Laying the bike on it’s side for. few hours to try and let the oil soak and loosen up the clutch plates… both to no avail so I set to with probably the most major job I have done on the bike, replacing the clutch. At first it didn’t want to come apart with the kick start level and starter motor live bolt fighting me so I left it soaking in Plus Gas for 48 hours and came back to it.

A gear puller I had picked up in between made light work of getting the kick start off and despite the starter motor live connection bolt being now made of toffee (the rubber cover acts as a nice water bowl for this to sit in) I managed to work it loose with some mole grips after removing the exhaust for better access. Which for the first time in my lifetime the exhaust head bolts came out as if they had just been put in, I can only assume it was the liberal Plus Gas and patience. Everything now out the way I was able to remove the side cover and slide it off, followed by unbolting the clutch springs. After which the clutch pack came out as one, the friction plates and metal plates all stuck together with rust.

With them removed I decided it wasn’t worth cleaning them and putting them back in as the friction material was likely compromised and I didn’t want loads of small rusty particles flowing round the engine in the shared oil. A new Gecko set was ordered and a couple of days later with a new gasket and some minor swearing after sheering a bolt and having to drill it out and replace it was back together with a new fresh clutch.

MOT Day

Once some insurance and tax had been sorted I got an MOT booked and that is when I realised I was missing a few things I needed to put it back together, a little rifling through the spares draws later and some suitable bolts and fasteners were found to get it looking back like a bike.

I had also after getting the clutch done managed to do a better job of refitting the screen, engine bars and fitted the new Chinese chain oiler which fits and works a treat. Unfortunately I didn’t get round to fitting the hand guards because they didn’t quite clear the levels or so I thought.

Anyway it went in for the MOT, riding it up the step hill to the estate was fun and took me back to being a kid again. I laughed my ass off all the way up the hill… After Failing initially on headlight aim, the local garage are excellent and they just got on and corrected it for me for no charge and put it back through passing with two minor advisories. 1. corrosion on the front forks (I knew about this but it wasn’t effecting performance or leaking dangerously). 2. Bent front brake lever, it’s obvious when you look at it and explains why the hand guards wouldn’t fit but somehow my brain had just chalked it down to a weird shape lever…

Finally it was ready to go to it’s new home, now I just had to get it there.

New Home Day

It’s new home in the New Forest is about 80 odd miles away from mine, so I made a day of it and gave the bike a proper shake down in the process. I started with a ride from High Wycombe to Winchester for 9AM to meet a biking buddy for breakfast, I actually got there decidedly early the bike not missing a beat and managing to carry my heft up to 55mph on the flat.

Following breakfast it was on to meet another mate in Chandlers Ford and take a ride with him upto Portsdown hill on the back roads like we did when we were first biking as teenagers most nights… Then back down from Portsdown to the New Forest to pick up a tent before heading to it’s final destination.

Just before this my mate had point out the tyres looked a little low, I hadn’t checked them as they had new rubber and had been inflated when fitted. Although they weren’t dangerously low they were not at the recommended pressure for the load so I cranked them up to the correct pressures. What a difference, the bike suddenly was more eager with my weight on hitting 65MPH on the flat and no doubt capable of reaching 70MPH with a longer run.

The new owner was most pleased with her new bike and putting her CBT to practice, here are some photo’s I took before the ride down. There are a couple of minor finishing touches that needed doing, the L plates needed fitting, the under tank plastic air trim things needed fitting and the hand guards that are still in my garage will be fitted at a later date after the level has been straightened.

Overall the bike did about 150 miles that day with my rather heavy body on and some bits in the top box / on the rear seat for sections it didn’t miss a beat and the chain oiler worked a charm. I am looking forward to joining it and it’s new owner on some rides hopefully in the not to distant future.

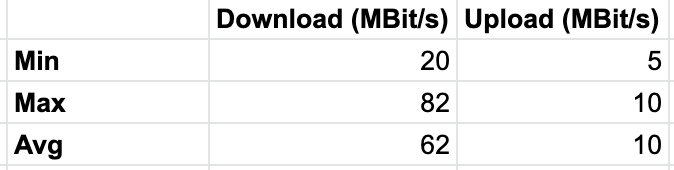

What did it cost in the end…

With purchasing for £150 I was hopeful that it would work out around the £500 on the road but with the extra issues and sprinkling a few accessories for better comfort and for the bikes long term betterment it came out at just under £800 and thats not accounting for fuel to get it down to it’s new home.

Overall this is still a good preposition as it has new brakes, tyres, chain and sprocket. Thus everything it should need general wear and tear wise for the next couple of years is covered. With a clean and a few finishing touches I reckon I could easily sell this for £900 and more likely get 1100-1300 for it on the current market. So although I was never in it for the profit, it at least is never going to be a loss if I were to need to sell it. However it just goes to show that even a 125 with cheap parts and that has low miles and should be a gem of a project can still rapidly rack up a hefty parts bill. If I had paid more than £150 I would be in the red…